Mixing & Agitation

We'll keep your fluids in motion

Mixing is the movement of fluids and solids, which is accomplished by an agitation source.

How it works

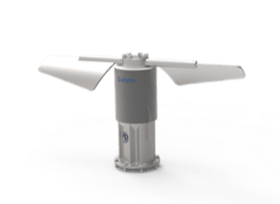

A mixer, or agitator, is a machine installed in a tank to achieve the desired process or product in the tank. PG are the world wide market leader for mud agitators. Learn about our PG Submix Mud Agitator.

Typical processes we solve are;

- Agitation to avoid sediments in the low part of a tank. Sediments is a typical challenge for waste water treatment plants, in drilling muds tanks, scrubber sludge tanks and fish ensilage tanks.

- Agitation to maintain the tank product homogeneous. When drilling mud is used and pumped down in the well it is essential that it has the correct density and desired viscosity. By using the correct agitators the density and viscosity can be guarantied in the hole tank volume.

- Mixing to blend products mechanically. Fish waste should be treated with enzymes, acids or other chemicals as fast as possible. The most efficient way to stabilize the ensilage is to use a mixer in the tank. Mixing is the way to ensure that the minimum of spent chemical can treat the maximum of ensilage.

- Heat exchange. The tank wall can be used as a heat exchanger. To increase the heat transfer an agitator is used to increase the velocity of the fluid inside the tank.

Download Product Sheet

PG Submix

The challenge

Variation in viscosity and mass causes multiple challenges in a tank. In order to have a successful agitation system, we collect data, do calculations and analyses before the the correct design is choosen. Input like tank geometry and fluid physical properties (density, particle size and content, viscosity and temperature) all play major parts on the result.

It is important to understand the process in the tank;

- What enters the tank?

- What should happen in the tank?

- What should the optimum product be for the downstream process?

Based on the given information we will calculate the correct PG-SUBMIX to solve your motion challenges.

Read more: PG Submix Mud Agitator

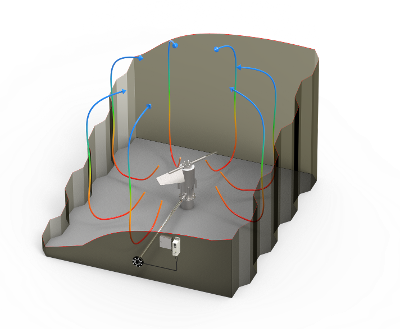

Image: Illustration of a Submix agitator in a mud tank

The Solution

PG Flow Solutions have delivered agitators and mixers from the early 1980`s. We know how to make your liquids move.

The optimum rheology was discovered by laboratory scaled test. Based on the laboratory tests scale up rules were established and are still in use. By selling more than 3 000 PG-SUBMIX worldwide without any claim related to the rheology it is considered as proven technology.

The design guidelines are the same today as in the 80's.

We find the optimum impeller geometry to the process and the tank to minimize the energy consumption. Place the impeller at the correct location in the tank. Install the drive directly coupled to the impeller to avoid energy transition by gearboxes and shafts.

When the process is not verified by previous installations PG will do a CFD analysis of the tank and agitator to verify the rheology and the required installed power.

All PG-SUBMIX are built in the PG workshop in Sande Norway. Typical materials are Steel, Stainless steel and Super duplex steel.

Read more: PG Submix Mud Agitator

Explore how we solve your flow challenges.

We're ready to discover and discuss your opportunities.

Browse through some of the typical application areas we assist our customers with.

No matter what flow challenge you face, we have the experience and expertise to choose the right solution, components and technology to solve your challenges.

#1 Design

Describe your challenge.

In cooperation with technical supervisors and the workshop, we will draw the first solution concepts in the form of descriptions, sketches, or models to solve your challenge.

We proceed with GA drawings, which illustrate dimensions and functionality. Together we discuss, test, and optimize.

#2 Build

Now, let's build it!

We cut, bend, machine, weld, assemble, treat and test a variety of components in-house. From the design we have detailed steel drawings that describes which parts we must process.

When all the steel parts have been made and welded together, we will normally carry out surface treatment with paint or acid pickling.

#3 Operate

We'll take care of you.

For some projects, our presence will be needed to carry out assembly and commissioning, other times the customer takes care of this process with support from us.

Our main goal is to verify that the systems and components are installed and operated according to the project- and client requirements.