Support

Spare parts, repair, maintenance or something else. Our experienced service team stand ready to keep your operations moving.

Call: +47 66 77 56 00

E-mail: aftersale@pg-flowsolutions.com

View our Support FAQ

PG's dedicated to support our customers lifecycle operations!

We offer a range of support and after sales services. We offer replacement pumps and motors, modifications and upgrades, on site inspections, maintenance plans, re-engineering, testing, training and courses, spare parts and more.

Read about our services below or get in touch to hear more about how we can help you.

All inquieries will be handled as quickly as possible by our dedicated After Sales team.

Global expertise – local commitment

PG Flow Solutions provides pump service, repair and lifecycle support for customers worldwide. Our multidisciplinary team of service engineers covers mechanical, electrical, hydraulic, automation and process disciplines, ensuring reliable performance throughout the equipment’s lifetime.

Commissioning and start-up

A correct start-up ensures long-term reliability. Our service engineers support the commissioning phase to verify installation, fine-tune the pump systems, and optimise surrounding processes. With PG on site, you secure a smooth transition into production and extend the lifetime of your equipment.

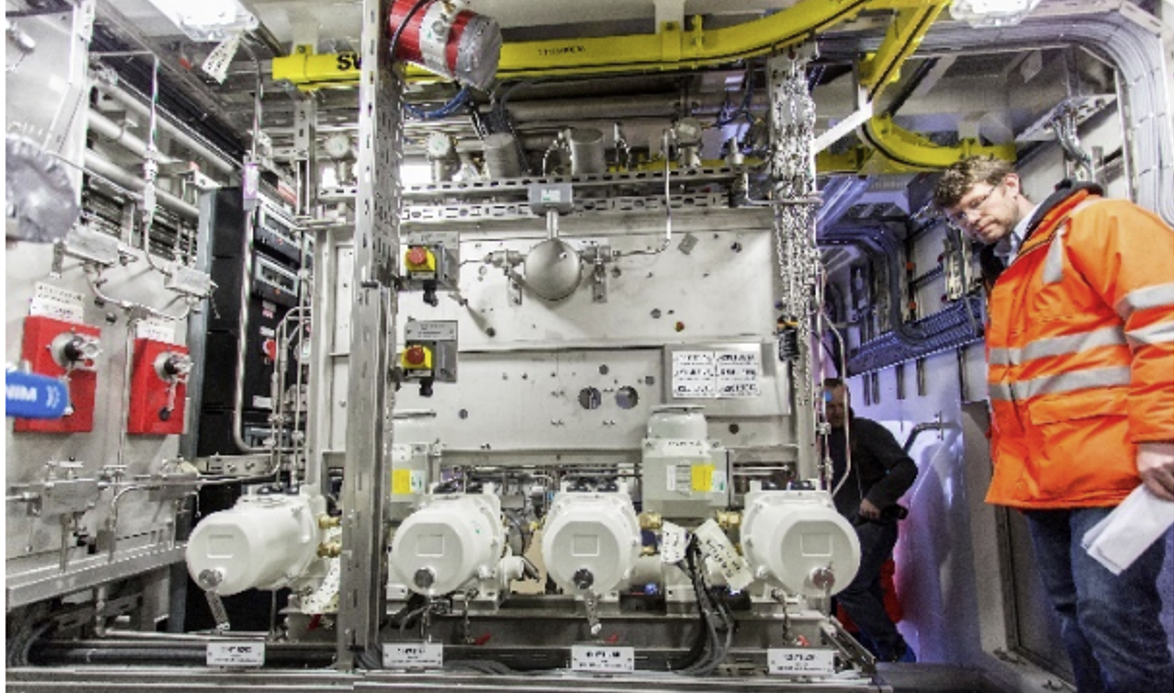

On-site overhaul and repair

When operating hours are high, maintenance becomes essential. PG’s skilled service engineers perform on-site overhaul and repair for a wide range of equipment, including centrifugal, screw, plunger and diaphragm pumps. Wherever your equipment is located, our team ensures professional maintenance and reliable results.

Troubleshooting and technical support

As systems age, unexpected failures can occur. Our engineers are experts in troubleshooting complete pump systems and processes. We identify root causes, restore performance, and help you avoid unplanned downtime.

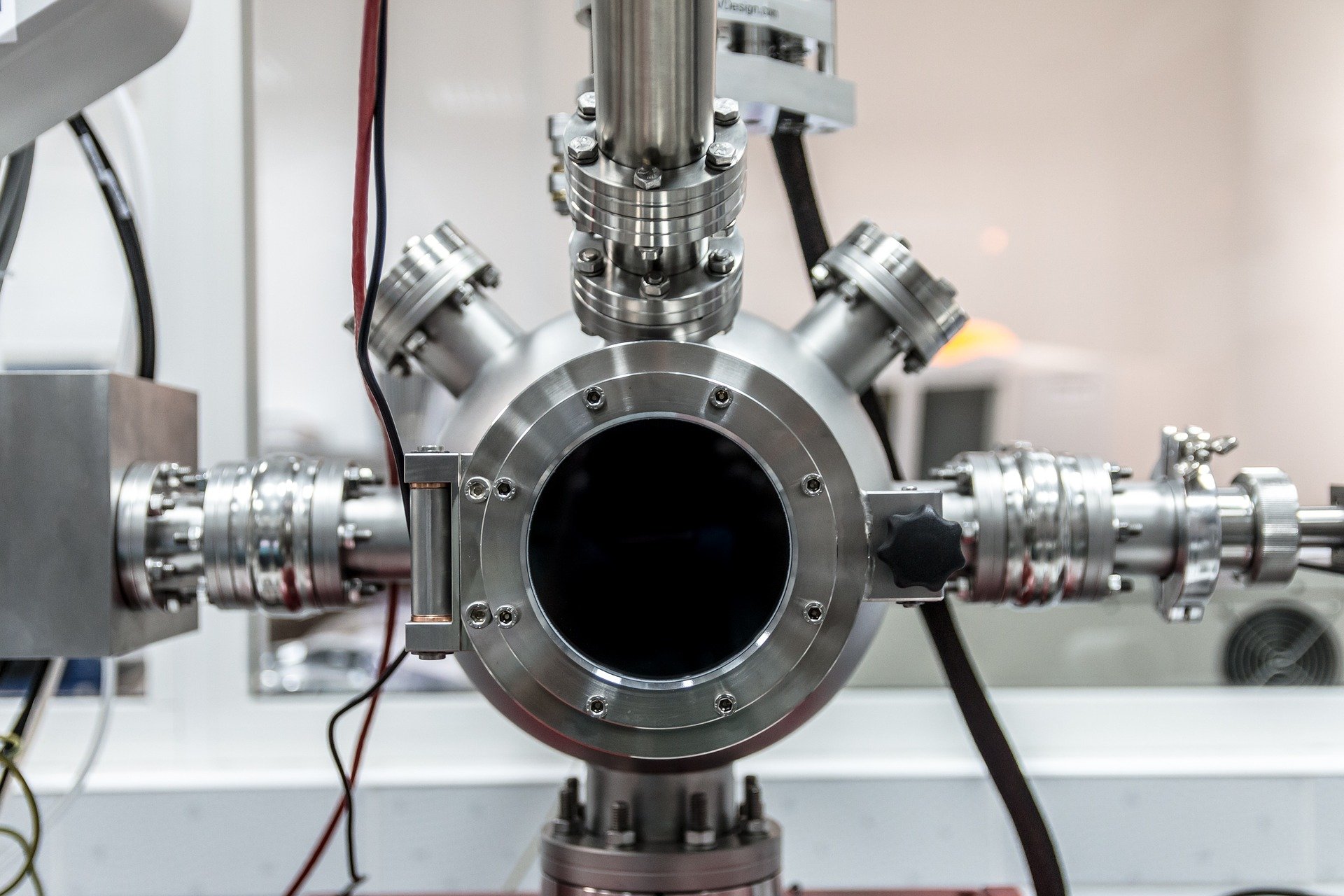

Workshop repair and testing

In our modern workshop facilities, we carry out complete pump repairs and overhauls. Each unit is inspected, documented and reported with recommendations and an offer for spare parts and work required to restore original performance.

Our in-house test facilities include two test pits (5 × 5 m, 8 m deep) allowing flow testing up to 10 000 m³/h and pressure testing up to 2 000 bar. We perform performance verification, factory acceptance tests, and testing of refurbished pumps at actual duty points.

Service and spare parts FAQ

Looking for more details about our maintenance routines, spare part availability, or response times?

Visit our Service & Spare Parts FAQ below for quick answers to the most common customer questions.

Confidence through service

PG Flow Solutions offers full lifecycle support – from commissioning and maintenance to testing and upgrades. With global reach and industry-specific experience, particularly within the marine and offshore sectors, we help you keep your pumps performing reliably, year after year.Get in touch with our service team to discuss maintenance, repair or testing of your equipment – and keep your operations running at peak performance.

PG LIFECYCLE SERVICES FAQ

Here are answers to some common questions regarding PG Service and Spare-parts for PG pumps. Shold you have other questions of not fiind the answer you are looking for, please do contact our Aftersales team.

PG has a highly qualified multidisciplinary team of service engineers who travels worldwide to serve our projects. Our Team is handling both mechanics, process, electrical, hydraulics, automation and are specially trained for pumping processes.

Service intervals depend on the pump type, operating conditions, and process environment. All PG pumps and systems include documentation specifying recommended intervals. If you can’t find your documentation, contact our service team — we’ll advise on suitable maintenance schedules for your equipment.

Normal wear parts vary by pump design and duty. Components typically affected by wear include:

- Mechanical seals

- Bearings

- Shafts and axles

- O-rings and gaskets

Our aftermarket team can recommend inspection and replacement intervals based on your PG pump model and process.

Each PG system is delivered with documentation that lists recommended spare-part packages. If your documentation is missing, contact our spare parts team and we’ll help identify the correct parts for your installation.

The more details you include, the faster we can assist. Please provide:

- PG project number

- Serial number

- Project or vessel name

- Pump model

If some of this information is missing, send us what you have — we’ll identify the equipment.

All PG pumps (PG Flow Solutions or Ing. P. Gjerdrum) include a TAG plate showing serial number, project number, and model type.

- Fill out the service request form (click here to download).

- Send it to aftersale@pg-flowsolutions.com.

- You’ll receive a reference number for your case.

- Mark your shipment with this number and send it to: PG Flow Solutions AS, Lærumveien 100, 1374 Sande, Norway.

Yes. We can perform on-site or in-house testing to verify flow, pressure, and performance according to datasheet specifications or customer requirements.

Yes — we understand downtime is costly. Our service team strives to meet your needs even on short mobilization timeframes. Contact our Aftersales team to arragne priority service.

Yes. We provide customized service agreements to ensure predictable maintenance and minimized downtime. Contact our Aftersales team to discuss available options.

We serve customers worldwide, shipping to all countries within Norwegian laws and export regulations.

We coordinate logistics and customs documentation for international service and repair work performed in Norway. Multiple shipping alternatives can be arranged depending on urgency and location.