Rotary Press – Highly Efficient Dewatering Solution

Highly efficient, low OPEX solid-liquid separation for fish-waste, wastewater, biogas and industrial applications.

Fournier Rotary Press™ - an efficient rotating filter press with high capture rate and low operating cost.

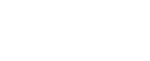

The Fournier Rotary Press™ is a solid-liquid separation technology that offers significant advantages over traditional dewatering solutions. With distinct models suitable for high fiber-containing sludges (CVP) and biological sludges (CVH), it offers a highly effective dewatering process that uses less polymers, power and water compared to other technologies.

The rotary press is well suitable for dewatering a range of sludge - from fish waste to biomass, wastewater and pulp and paper.

The rotary press achives a high capture rate, ensuring good solid-liquid separation and produce a dry cake with low moisture and high rate of Total Solids (%TS) content. This results in a cleaner reject-water-minimizing

The high efficiency, low power and polymer usage of this automated, modular and scaleable design, offers a long term sustainable solution with low OPEX.

What is the Fournier Rotary Press™ and What Applications is it for?

The Fournier Rotary Press™ is a compact and fully automated dewatering system designed for reliable, low-noise operation.

Its slow-rotating, enclosed design ensures clean, odour-free performance with minimal supervision and maintenance.

Built on a modular platform, the Rotary Press can easily be expanded or adapted to meet changing capacity needs — delivering long-term flexibility and efficiency.

For customers in biogas, wastewater treatment, aquaculture, and industrial processes such as paper mills and process industries, the Rotary Press offers:

-

Compact footprint and quiet, enclosed operation

-

Automated control for continuous, unattended performance

-

Modular and scalable design for future expansion

-

High throughput with consistent dryness and clean filtrate

-

Low energy use and reduced polymer consumption

How It Works

The Rotary Press dewaters sludge through slow, continuous rotation and controlled pressure — a simple yet highly effective process that delivers consistent dryness, low energy use, and minimal operator attention.

The Fournier Rotary Press™ is a fully enclosed and automated dewatering system with integrated sludge and polymer feed.

Its operation is simple, reliable, and energy-efficient — using slow rotation (about 1 r.p.m.) to separate water from solids with minimal wear and noise.

Process overview:

Feed – Flocculated sludge enters the rotating channel formed between parallel, chrome-plated stainless-steel filter elements.

Filtration – As the sludge moves forward, free water passes through the filter surfaces, while solids are gently compacted.

Pressure build-up – A restrictor arm creates controlled back pressure, increasing dryness as the sludge progresses through the channel.

Discharge – The process ends with a consistent, dry cake and a clean filtrate — ready for reuse or safe disposal.

With its low-speed, continuous operation and enclosed design, the Rotary Press provides quiet performance, long service life, and stable throughput across a wide range of sludge-handling applications.

Technical Highlights

- Available in 1 to 8 channel setups

- slow rotation speed: 0.5 to 2 rpm.

- Cake total solids percentage varies: 15% to >58% based on sludge type.

- Filtrate total suspended solids capture rates: 95% to 99.5%, dependent on sludge type and polymer usage.

- Minimal internal abrasion, even with abrasive sludges.

- Energy consumption ranges: 2 to 7 kW/hr per dry ton of sludge.

- Flow rates per hr/dewatering module: 2 to 12 m3/hr, dependent on sludge type and dewaterability.

Industries and Applications

The Rotary Press is used across a wide range of applications where efficient solid-liquid separation are essential:

-

Industrial wastewater – Reliable dewatering of sludge from various industrial processes with low energy use and minimal operator attention.

-

Biogas production – Efficient dewatering of digestate and biosludge for easier handling, reduced transport cost, and improved nutrient recovery.

-

Aquaculture – Compact and quiet solution for sludge dewatering in RAS and fish processing systems, supporting clean water discharge and compliance.

-

Pulp & paper – Continuous, low-maintenance dewatering of fiber and primary sludge for reduced waste volume and easier disposal or reuse.

-

Municipal treatment plants – Automated, enclosed system providing clean operation, reduced odour, and lower operating costs for municipal sludge handling.

Improves working enviroment and stress

Full-scale pilot testing

Pilot testing is the first step in evaluating how the Rotary Press performs on your specific process stream.

PG have two containerized mobile test units availible, offering full-scale pilot testing with your unicue sludge. on-site. Our test units can easily be transported to any location in Europe (excluding France).

Want to learn more?

PG is the European* distributor ofthe Fournier Rotary Press.

To learn more on how the Rotary Press can help solve your enviromental and sludge-handling challenges - see our subsidiuary company PG Cleanwater Solutions: www.pgcleanwater.com

Want to Know More About This Product?

Our team of experts is ready to help you find the right configuration for your application. Contact us for detailed specifications, custom options, or advice on integration into your system.

Wojtech Sargalski

Sales Manager Norway

Telefon +47 901 14 268

Epost: ws@pgcleanwater.com