VSEP – Membrane Filtration system

Efficient waste water filtration - removes >90% of nitrogen, phosporus, PFAS and other contaminants.

Advanced membrane technology for modern waste water treatment.

The VSEP (Vibratory Shear Enhanced Processing) system uses controlled vibrations to keep membranes clean and efficient — achieving up to 99.9% nitrogen removal while recovering clean water and valuable nutrients.

Value in Biogas and Nitrogen Removal

When integrated with Rotary Press dewatering, VSEP forms a complete, two-stage treatment solution for biogas and wastewater plants.

-

Rotary Press separates solids and reduces sludge volume.

-

VSEP treats the liquid fraction (reject water or centrate), removing nitrogen, phosphorus, and PFAS.

-

Combined, they deliver up to 99.9% nitrogen reduction and clean water for discharge or reuse — with minimal energy use and operator attention.

This approach supports circular resource use by returning nutrients to agriculture and protecting waterways from eutrophication.

What is VSEP and Why It Matters

VSEP (Vibratory Shear Enhanced Processing) is an innovative membrane filtration system developed and patented by New Logic Research Inc.

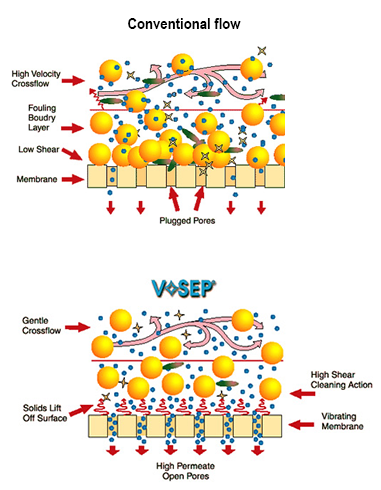

Unlike conventional filtration, VSEP uses controlled vibration to keep the membrane surface clean during operation.

This unique and tested technology delivers higher throughput, lower maintenance, and superior contaminant removal — even in demanding applications such as sludge, digestate, and industrial effluent treatment.

For customers in the water, wastewater, and biogas industries, VSEP provides:

-

Reliable compliance with strict discharge regulations

-

Significant reduction of nitrogen, phosphorus, PFAS, and heavy metals

-

Reuse of clean water and recovery of valuable nutrients

-

Low OPEX and long membrane life

How It Works

The VSEP system combines an ultra-fine membrane filter with a powerful electric motor that generates vibrations through an unbalanced shaft. The vibration creates a shear wave across the membrane surface, preventing fouling and maintaining continuous flow.

Process overview:

-

Feed – Liquid (such as sludge reject water or digestate) enters the VSEP module.

-

Vibration – The membrane pack vibrates rapidly, generating shear forces that keep particles suspended.

-

Filtration – Clean permeate passes through the membrane, while solids and contaminants remain in the concentrate.

-

Recovery – The result is clear water suitable for reuse and a concentrated stream rich in nutrients or solids for further processing.

This dynamic action allows VSEP to filter fluids that would quickly clog traditional RO, UF, or NF systems — resulting in higher recovery rates and longer uptime.

Technical Highlights

- Membrane area Up to 1,000 ft² per module

- Operating pressure Up to 1,000 psi (70 bar)

- Vibration frequency ~50 Hz (1,500 rpm equivalent)

- Recovery rate Typically 70–95% depending on feed composition

Modular configuration Stackable units for scalable capacity - Membrane types RO, NF, UF, MF — polymeric or ceramic

Industries and Applications

VSEP is used across a wide range of applications where efficient solid-liquid separation and nutrient recovery are essential:

-

Municipal wastewater treatment – Nitrogen and phosphorus removal, polishing of reject water, effluent reuse.

-

Biogas and anaerobic digestion – Treating digestate, recovering clean water, and concentrating nutrients for fertilizer.

-

Industrial wastewater – Handling high-strength or complex effluents from food & beverage, pulp & paper, chemical, and mining sectors.

-

PFAS and heavy metals removal – Advanced separation of persistent contaminants from process streams.

-

Water reuse and recycling – Enabling circular water management in industries and treatment plants.

Pilot testing

VSEP Pilot Testing

Pilot testing is the first step in evaluating how VSEP performs on your specific process stream.

A compact, mobile pilot unit allows real-world testing of filtration performance, recovery rate, and contaminant removal efficiency — including nitrogen, phosphorus, PFAS, and other pollutants.

Want to learn more?

To learn more about the VSEP system can help solve your enviromental and discharge challenges - see our subsidiuary company PG Cleanwater Solutions: www.pgcleanwater.com

In 2025 PG and PG Clean Water Solutions signed an distribution agreement with US-based New Logic Research Inc.

See even more information on VSEP at their website - www.vsep.com

Want to Know More About This Product?

Our team of experts is ready to help you find the right configuration for your application. Contact us for detailed specifications, custom options, or advice on integration into your system.

Wojtech Sargalski

Sales Manager Norway

Telefon +47 901 14 268

Epost: ws@pgcleanwater.com