#2 Build

- What happens in the building phase?

We cut, bend, machine, weld, assemble, treat and test a variety of component in-house.

In this phase we develop the new solutions or product. Prototypes are built and tested in our in-house facilities. Assembled components, connected with automation, systematics and other electrical components.

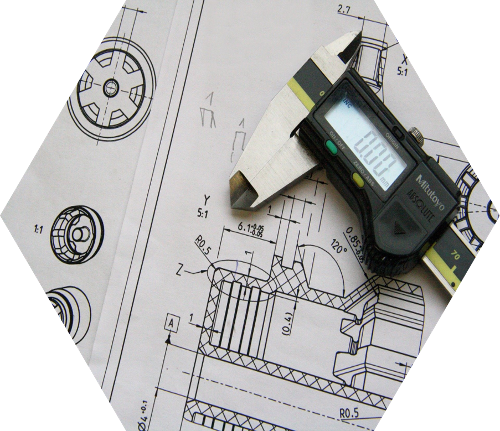

The production process starts in the steel workshop. From the design phase, the production department gets detailed descriptions of the prototype.

Steel drawings describes the parts we must process. When all the steel parts have been made and welded together, we normally carry out surface treatment with paint or acid pickling.

After surface treatment, the parts are moved on to the assembly hall, where the parts are assembled according to plan.

When the mechanical part is assembled, we move one to electrical components such as automations and control systems.

Once the product is assembled, we will run tests. In our faciliteis we can carry out several different tests.

- Rotation test to check that elements that are to rotate do just that.

- Static pressure testing by filling a chamber or a pump.

- Test pressure level to detect any cracks or deformations.

We have available two large test pools of 5 x 5 x 8 meters. Here we test equipment and components with actual flow.

- We can execute flow test up to 10 000 m^3/h

- Pessure test up to 2 000 bar.

- Equipment test up to 1.4 MW

- 6 installed frequency converters

- Voltage capacity up to 690V.

After testing, the product is shipped out to location. Before shipping, there is packing (for safe shipping) and preservation (ex. putting on tectyl) to prevent rusting, filling pumps with liquid to prevent them from freezing and cracking.

A product or solution is considered to be in the operational phase when it has been completed from production and delivered to the customer for assembly and commissioning.

How to get started

Learn about how we work.

Dive into the previous step (Design) and next step (Operation)

#1 Design

Describe your challenge.

In cooperation with technical supervisors and the workshop, we will draw the first solution concepts in the form of descriptions, sketches or models to solve your challenge.

We proceed with GA drawings, which illustrates dimensions and functionality. Together we discuss, test and optimize.

#3 Operation

We'll take care of you.

For some projects, our presence will be needed to carry out assembly and commissioning, other times the customer takes care of this process with support from us.

Our main goal is to verify that the systems and components are installed and operate according to project- and client requirements.