Solving Flow Challenges Across Industries

From Idea to Operation

PG Flow Solutions designs and delivers engineered systems for demanding environments – moving, mixing, separating, and protecting with precision.

We combine mechanical expertise, process understanding, and hands-on industry experience to create flow technology that performs safely and efficiently.

We engineer complete flow solutions that keep your operations moving — across marine, energy, aquaculture, and industrial sectors. From the first idea to full operation, we’re your partner in performance, reliability, and sustainability.

Industries We Serve

We combine mechanical expertise, process understanding, and hands-on industry experience to create flow technology that performs safely and efficiently.

Sustainable flow systems for both sea-based and land-based fish farming. From live fish transport and ensilage to sludge handling and water circulation, our solutions are designed for biological safety, uptime, and efficiency.

Reliable flow technology for biogas, renewables, and offshore energy. We help operators meet sustainability targets through efficient dewatering (Rotary Press, VSEP) and durable process systems built for uptime and compliance.

Engineered systems for wastewater treatment, pulp & paper, and biogas applications. Our Rotary Press, VSEP, and PG-Submix deliver dependable performance in tough industrial conditions, helping reduce waste and operating costs.

Decades of experience in offshore, shipping, and well-boat systems. We deliver cargo handling, fire suppression, and pumping solutions for vessels ranging from OSVs and ferries to well-boats and next-generation fuel carriers.

Products & Technologies

We engineer and deliver complete systems, combining in-house design with trusted partnerships to ensure quality, serviceability, and long life.

Our key technologies include:

- Marine Pump and Cargo solutions for Offshore Supply, FPSO and FLNG vessels

- Bespoke API-approved pump skid systems for Oil & Gas and Offshore wind installations

- PG–Propeller Pumps – Efficient, durable circulation for aquaculture and marine use

- PG–Submix Agitators – Reliable mixing for sludge, cargo, and tank operations

- Rotary Press – Continuous Solid-Liquid Seperation for biogas, industrial and aquaculture applications

- VSEP – Vibratory membrane filtration for nitrogen removal and recovery

- Fire Suppression Systems – Water mist, foam, deluge, and inert-gas protection

- Hydroflow – Fish-friendly transport and circulation for well-boats

What sets us apart:

When reliability, uptime, and safety matter most.

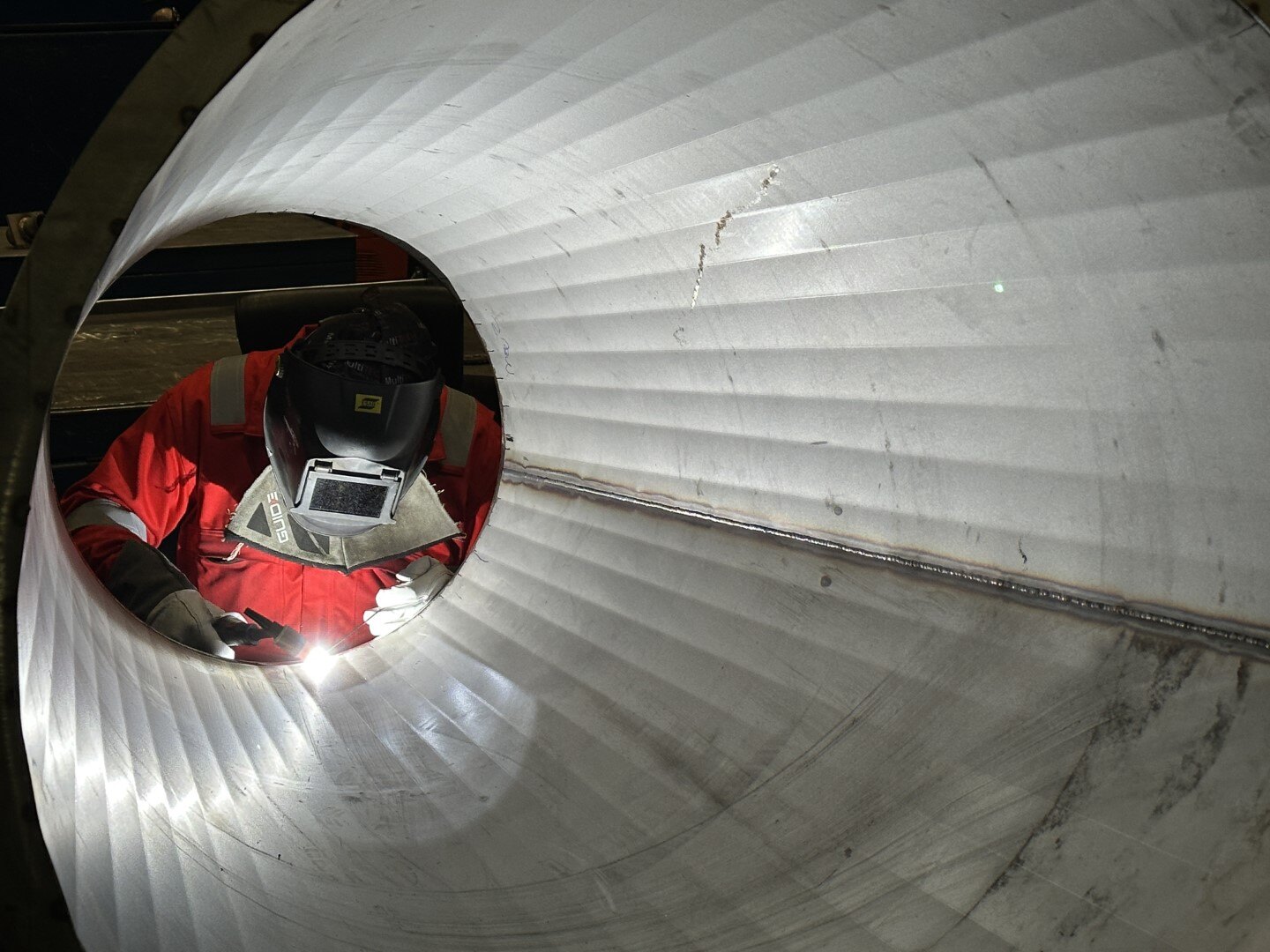

Service & Lifecycle Support

From maintenance and repair to custom steel fabrication – PG Flow Solutions is your long-term industry partner.

Our multidisciplinary team provides global pump service, spare parts, and lifecycle support, backed by in-house expertise in mechanics, hydraulics, automation, and welding.

Whether it’s offshore, on-site, or in our workshop, we secure reliable performance and extended lifetime for your equipment.

Latest News & Insights

PG Flow Solutions at Aqua Nor 2025: Energy-Optimised Technology for Modern Aquaculture

Meet PG Flow Solutions at Nor-Shipping '25 3. - 6. june - stand E03-12 -- join us aboard "Caliope V" at the docks.

Join us at the 2025 OSJ Conferences in London!

A solution to reducing gas flaring and increasing efficiency.

Let’s Solve Your Flow Challenge

Looking for a trusted partner to design, build, and support your flow systems?

Let’s explore how we can help.